As someone working in the supply chain space, you must have, at some point, wondered, “Is the hype around AI in the supply chain real? Are organizations really taking the leap with AI?” Well, we have the answers for you! According to Statista, AI adoption has spiked, with 68% of companies adopting AI in their supply chain operations by 2025. And why not? The benefits are tangible, with respondents reporting cost decreases and revenue jumps in the business units deploying generative AI.

Now that you know AI is indeed transformative for the supply chain, your next questions may be–what are the right use cases and applications of AI in supply chain management? How are industry leaders implementing AI? This blog post answers these questions and provides practical insights into the role of AI in supply chain.

Let’s begin with the impact of AI on the supply chain industry.

How is AI transforming the supply chain landscape?

Businesses are bringing artificial intelligence into their supply chains to cut costs, speed up distribution, and get ahead of potential disruptions. Leveraging advanced analytics and decision intelligence, AI supply chain management helps companies make faster and more accurate decisions at strategic, operational, and tactical levels.

Notably, generative AI adoption is surging, with 65% of supply chain organizations regularly using it – nearly double the rate from just ten months ago. Companies leverage generative AI across marketing, sales, product development, and IT functions to streamline workflows, enhance production efficiency, and enable virtual logistics management.

German software firm Celonis is working with Mars to use generative AI for combining truck loads. “We can proactively tell them, ‘Here are all the truck loads that you have going out that you should consolidate,'” said Celonis Chief Executive Alex Rinke. This approach has “reduced manual touches by 80% and also made them more efficient as a company because they reduced shipping costs, reduced emissions and improved on-time shipments.”

AI’s ability to quickly sort through massive datasets, make predictions, and respond to queries in natural language is driving its rapid adoption. Early implementations focus on optimizing logistics operations, improving decision-making processes, and enhancing customer support functions. AI also contributes to supply chain resilience by addressing disruptions and complex global operations. Additionally, the adoption of AI spans various industries, from food and beverage to pharmaceuticals and agriculture.

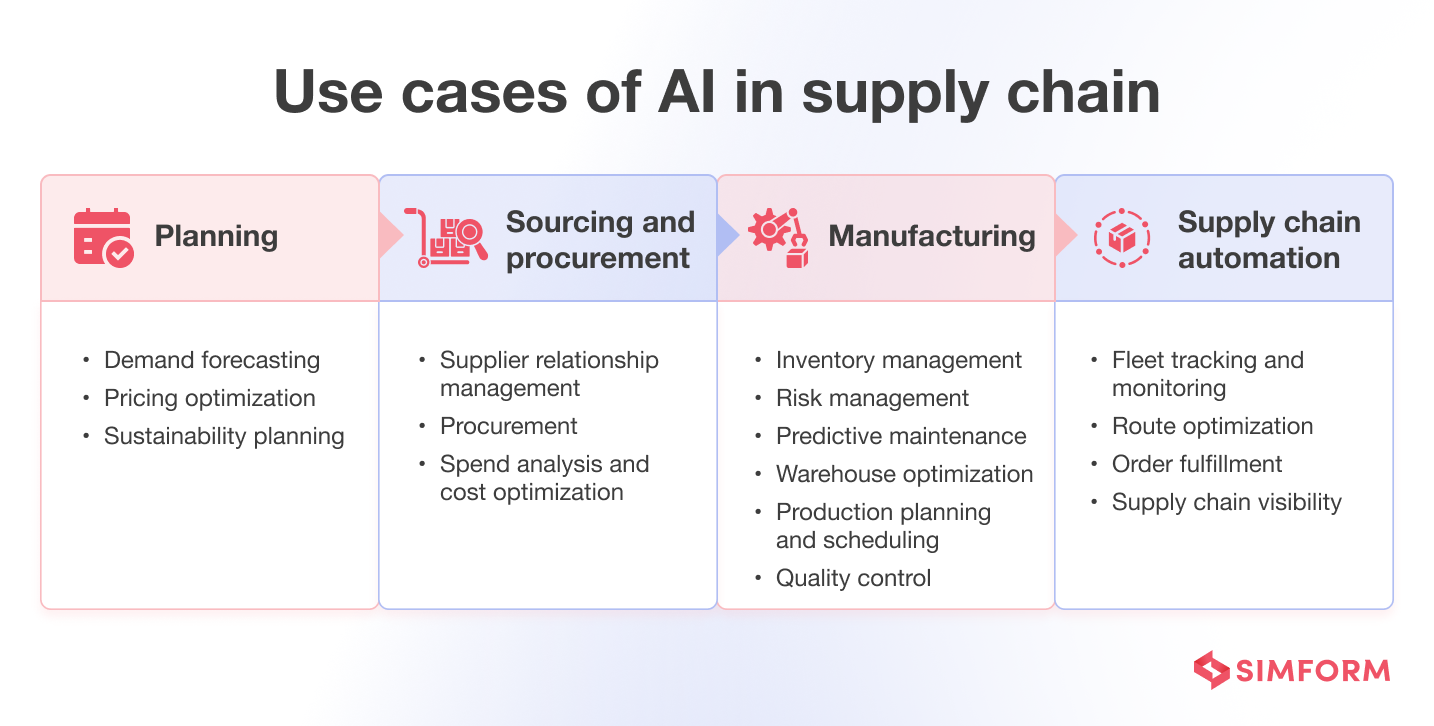

Use cases and applications of AI in the supply chain with examples

A. Planning

#1. Demand forecasting

Traditional demand forecasting methods like time series analysis and regression models rely on historical sales data to identify trends and seasonality. So they don’t consider factors like changing consumer preferences, market disruptions, and the impact of variables like weather events or economic shifts, leading to less accurate forecasts.

AI addresses these limitations by leveraging machine learning algorithms to process vast amounts of data from sources like online search trends, website traffic, purchase histories, social media sentiment, competitor actions, and macroeconomic indicators like GDP growth and inflation rates. This enables companies to generate more accurate, granular, and dynamic demand forecasts, even in market volatility and uncertainty.

Antuit.ai offers a Demand Planning and Forecasting solution that uses advanced AI and machine learning algorithms to predict consumer demand across multiple time horizons. The system generates hyper-localized forecasts for every SKU and location by incorporating factors like local events, seasonality, pricing, and promotions. Once done, its AI-powered segmentation categorizes forecasts into “no-touch (no human intervention),” “low-touch (minimal human intervention),” and “high-touch (significant human intervention)” areas to streamline the planning process.

#2. Pricing optimization

Pricing optimization today is not as easy as it used to be. The customer now has access to resources like online catalogs, specialized search tools, etc, to compare the prices of different products, which makes setting the optimal price a top priority for businesses.

Here’s how AI is helping organizations with pricing optimization:

- Dynamic pricing: By continuously monitoring factors like competitor pricing, customer behavior, and market conditions, intelligent algorithms can adjust prices in real time to capture the optimal price point.

- Personalized pricing: Machine learning models can identify distinct customer segments based on purchasing history, price sensitivity, and demographic data. Businesses can then determine the ideal pricing strategy for each segment and maximize revenue without alienating price-conscious buyers.

- Promotional strategy optimization: AI can simulate the impact of various promotional strategies and recommend the most effective discounts or bundle deals to drive sales and profitability. This goes beyond simple rules-based discounting, using advanced algorithms to predict the complex interplay between pricing, demand, and customer behavior.

Accenture’s Solutions.AI for Pricing usess advanced AI and machine learning algorithms, including deep learning and game theory, to optimize pricing strategies in real-time. It offers capabilities like base-price optimization, discount personalization, and deal margin optimization across multiple industries. The solution also includes a pricing recommendation engine and multi-lever simulation tool, which help businesses quickly test and implement optimal pricing scenarios to drive profitability.

#3. Sustainability planning

AI is empowering organizations to make data-driven decisions that drive environmental, social, and governance (ESG) performance. Here’s how:

- Energy management: AI algorithms can monitor energy consumption patterns, identify inefficiencies, and recommend targeted interventions to reduce energy usage. For example, AI-enabled predictive maintenance can predict equipment failures to minimize downtime and optimize energy usage.

- Waste reduction: AI can forecast demand more accurately, enabling organizations to align production with actual needs and minimize overproduction. Additionally, AI-powered supply chain traceability and transparency solutions can track the flow of materials, allowing businesses to identify and address sources of waste and inefficiency.

- Product lifecycle management: By providing insights into the environmental impact of products, from sourcing to disposal, organizations can make informed choices, implement eco-friendly design practices, and collaborate with suppliers to improve sustainability throughout the product’s life cycle.

Walmart is developing an AI-powered waste management solution to predict, prevent, and proactively handle waste. The solution analyzes data to identify key waste reduction opportunities and drivers, then recommends ways to reduce waste, such as lowering prices, moving products, returning them to suppliers, or donating them.

The AI also identifies which items contribute the most waste in a particular store, considering factors like stock availability and seasonality. This information is presented to associates through an easy-to-use dashboard, allowing them to make informed decisions and learn from other stores’ best practices.

B. Sourcing and procurement

#1. Supplier relationship management

AI-powered supplier relationship management solutions leverage machine learning, natural language processing, and data analytics to help organizations select and manage the right suppliers for their products and services.

Some ways AI can optimize supplier relationship management:

- Supplier selection: ML models can analyze a vast amount of data on suppliers, such as quality, delivery, pricing, and customer reviews, to help you rank and select the best-fit partners.

- Supplier performance prediction: AI in supply chain can forecast potential supplier issues like financial troubles or quality problems before they occur. Predictive analytics on factors like past incidents, supply chain risks, and market volatility can generate supplier risk scores to guide your proactive interventions.

- Contract compliance: Natural language processing techniques can scan supplier contracts to detect non-compliance with regulations, ensuring you stay compliant with legal requirements.

A good example of AI in supply chain is how Ducab, a leading cable manufacturer, implemented an AI-powered supplier portal to streamline its supplier network. It enabled the automation of supplier pre-screening and self-registration, ensuring that only qualified suppliers get added to the database.

Moreover, the portal allowed Ducab to digitize and streamline various supplier management tasks, such as certificate tracking and profile updates. These and more AI features in the portal, have helped the company eliminate manual processes from their supplier relationship management operations.

#2. Procurement

AI and generative AI hold immense potential to transform procurement allocation processes. Here are some critical ways through which you can leverage these cognitive technologies:

- Global sourcing insights: AI can aggregate and analyze data from various third-party and public sources to identify shifts in global supply trends across commodities and products.

- Invoice data extraction: AI-powered invoice data extraction solutions can automatically extract relevant data from invoices within 30-60 seconds using computer vision and NLP. It can reduce fraud, improve processing times, and provide better spending insights.

- Automated compliance monitoring: AI-powered solutions can automatically compare payment terms, identify non-compliance rates between contracts and invoices, and detect duplicate invoices.

- Contract data extraction: NLP can extract and structure critical information from unstructured contract documents, such as start and end dates, payment terms, and references to master agreements.

- Contract lifecycle management: AI is being integrated into contract lifecycle management (CLM) tools to streamline the contract generation, negotiation, and risk identification process.

With nearly 200K purchase orders and 1.1 million invoices processed annually, Accenture Procurement Plus struggled to improve the accuracy and efficiency of assigned general ledger accounts during procurement.

They developed an AI-powered General Ledger Recommendation solution that analyzes historical purchase and invoice data to suggest the most appropriate general ledger account at the point of purchase. It was embedded directly into Accenture’s BuyNow procurement platform, which now helps buyers assign correct accounts and improve accuracy, efficiency, and cost of downstream accounts payable.

#3. Spend analysis and cost optimization

AI-powered spend analysis tools can rapidly categorize and analyze vast amounts of purchasing data across an organization. These systems use NLP and machine learning algorithms to automatically classify spend data into standardized categories, regardless of how individual vendors or departments may label items. This granular categorization allows procurement teams to identify consolidation opportunities, negotiate better contracts, and uncover maverick spending.

For cost optimization, AI models analyze historical pricing data, market trends, and supplier performance to recommend optimal sourcing strategies. These systems can predict future price fluctuations, suggest the best time to make purchases, and even automate routine procurement tasks.

C. Manufacturing

#1. Inventory management

Traditional inventory management relies on manual processes and historical data, while AI-based systems leverage real-time data and predictive analytics for smarter inventory management. Here are some of the applications of AI in inventory management:

- Sales forecasting: By analyzing historical sales data, current market trends, and changing customer behavior, AI-powered models can generate accurate sales forecasts, enabling companies to plan their inventory levels to meet fluctuating demand proactively.

- Inventory optimization: Reinforcement learning helps determine optimal reorder points, safety stock levels, and replenishment strategies, effectively minimizing the risks of overstocking and stockouts.

- Customer segmentation: Clustering algorithms and ML models can categorize customers based on their purchasing patterns, choices, and demographics, enabling businesses to tailor their inventory strategies according to different customer groups.

How did Simform help a global retailer streamline its inventory management?

A consumer electronics retailer partnered with Simform to optimize inventory management across 2,000 stores in 15 countries. They faced challenges with stockouts, overstocking, and inefficient order fulfillment. Simform developed a custom AI-powered inventory management solution built on AWS. Key components of the system included:

- Predictive demand forecasting: Leveraging Amazon SageMaker, we created machine learning models that analyzed historical sales data, seasonal trends, and external factors to accurately predict demand for each product across all stores.

- Dynamic inventory allocation: Using AWS Lambda functions, the system continuously adjusted inventory levels across the network in real-time, ensuring optimal stock distribution.

- Real-time supply chain visibility: We implemented a dashboard using Amazon QuickSight, providing the company with comprehensive views of inventory levels and potential issues across their entire network.

- Data processing and storage: Amazon S3 and Amazon RDS were used to store and manage vast amounts of inventory and sales data, while Amazon Kinesis handled real-time data streaming for up-to-the-minute analysis.

#2. Risk management

Supply chain risk management involves identifying, assessing, and mitigating potential disruptions and vulnerabilities across the supply network, from raw material sourcing to final product delivery. AI helps by enhancing capabilities to predict, prevent, and respond to supply chain-specific risks.

Real-time data analysis and risk detection

AI systems can process vast amounts of data from diverse sources such as weather reports, geopolitical news, and transportation logs in real-time. For instance, an AI model might analyze satellite imagery and weather forecasts to predict flooding risks in key manufacturing regions, allowing companies to proactively adjust production schedules or secure alternative suppliers.

Predictive analytics for proactive risk mitigation

By leveraging historical data and current trends, AI can forecast potential supply chain disruptions. For example, an AI system might predict a shortage of semiconductor chips based on global production data, consumer electronics demand trends, and geopolitical factors, enabling tech companies to secure inventory or develop contingency plans months in advance.

Enhanced supply chain visibility and rapid response

AI-powered tracking systems provide granular, real-time visibility into the movement of goods across the supply chain. If a shipment of perishable goods is delayed due to a port congestion, AI can automatically recalculate delivery times, assess the risk of spoilage, and suggest alternative routing or storage solutions to minimize losses.

#3. Predictive maintenance

As enterprises navigate the challenges of rising costs and supply chain disruptions, optimizing the performance and reliability of physical assets has become increasingly crucial. Powered by AI, predictive maintenance helps you extract maximum value from your existing infrastructure.

Here are the top use cases of AI in predictive maintenance:

- Predictive failure analysis: AI models can analyze sensor data, maintenance logs, and operational data to identify patterns and anomalies that indicate an impending equipment failure. It allows you to intervene proactively before a breakdown occurs.

- Optimized maintenance scheduling: By understanding the health and performance of your assets, AI can recommend the optimal maintenance schedule to maximize uptime and efficiency. It can also automatically trigger maintenance work orders.

- Prescriptive maintenance: AI can go beyond predicting failures. It can also recommend specific actions to address an issue, such as which parts to replace or adjustments to make, helping your maintenance team work more effectively.

- Asset life extension: AI-driven predictive maintenance can extend the useful life of your equipment by preventing unnecessary wear and tear, allowing you to extract more value from your capital investments.

How did Simform help a global water treatment company streamline its manufacturing capabilities with predictive maintenance?

Simform partnered with a global industrial equipment manufacturer (operating in 20 countries with over 100 product lines) to develop an AI-powered Asset Performance Management solution.

Our team utilized AWS services to create a comprehensive APM system which included the following:

- A predictive maintenance model built with TensorFlow on Amazon SageMaker, analyzing real-time sensor data from 50,000+ machines to forecast failures with 92% accuracy up to 2 weeks in advance.

- An asset health scoring algorithm that considers 150+ variables, including operational data, maintenance history, and environmental factors.

- A real-time anomaly detection system using AWS Kinesis for stream processing, capable of identifying unusual equipment behavior within seconds.

The solution integrates data from 12 different internal systems and IoT devices, processing over 2 terabytes of data daily.

Key results after 6 months of implementation included a 15% reduction in unplanned downtime, 28% decrease in maintenance costs, and $32 million in annual savings from extended equipment life and improved operational efficiency.

#4. Warehouse automation

Some of the critical methods and techniques through which AI can facilitate warehouse automation are:

- Autonomous Mobile Robots (AMRs) leveraging deep learning algorithms can navigate warehouses autonomously, transport goods efficiently, and adapt to changing environments.

- Language and image generation models can generate accurate product descriptions, labels, and process documentation, streamlining warehouse workflows.

- Computer vision enables automated item picking and packing, while NLP powers intelligent warehouse management systems and chatbots for customer support.

DHL Supply Chain has partnered with Robust.AI to develop an innovative fleet of AI-powered warehouse robots, starting with ‘Carter,’ a collaborative mobile robot for material handling.

This solution leverages advanced AI to optimize picking processes, adapt to real-time warehouse conditions, and generate data for improving layouts, staffing, and inventory management. The AI-driven robots are designed to enhance efficiency while complementing human workers, aiming to create a smarter, safer, and more reliable supply chain.

#5. Production planning and scheduling

Production planning and scheduling are crucial in supply chains for optimizing resource utilization, reducing costs, and ensuring timely product delivery to meet customer demand. Artificial intelligence enhances these processes in many ways:

- Real-time adaptability: AI systems can quickly adjust production schedules in response to unexpected events like machine breakdowns or supply chain disruptions.

- Efficient resource allocation: AI algorithms intelligently allocate resources by considering factors such as equipment availability, worker skill levels, and material availability.

- Integration with IoT and automation: AI-driven production scheduling integrates seamlessly with Internet of Things (IoT) devices and automation technologies. This integration enables real-time data exchange between machines and scheduling systems, enhancing production efficiency and agility through continuous feedback and adjustment.

A large hydrocarbon processing company implemented an AI-based solution to optimize production schedules and minimize manufacturing costs at their large polypropylene plant. The company integrated disparate data sources like demand forecasts, customer orders, production costs, and inventory into a unified data image. Based on these data, the machine learning models predict customer demand and configure optimization algorithms to generate optimal 60-day production schedules. It improved demand forecasting accuracy by 20% and incorporated over 2 million operational constraints from 20 categories.

How did Simform help a global car manufacturer optimize production planning and scheduling?

Simform partnered with a leading European car manufacturer (with operations in 12 countries and over 60 models in production) to optimize production planning and scheduling.

Our team leveraged Amazon SageMaker to create a sophisticated AI-powered solution which included:

- A demand forecasting model that analyzes historical sales data, macroeconomic indicators, and social media sentiment to predict demand with 95% accuracy up to 6 months in advance.

- A supply chain optimization algorithm that factors in 200+ variables, including supplier lead times, inventory levels, and production capacities across all facilities.

- A dynamic scheduling system that can re-optimize production plans in real time based on unexpected events like supply disruptions or sudden demand spikes.

The solution integrates data from 17 different internal systems and external sources, processing over 1 million data points daily.

After 12 months of implementation, key results included a 9% increase in overall production efficiency, a 35% reduction in manual planning hours, and $47 million in annual savings from improved resource allocation and reduced waste.

#6. Quality control

Conventional quality control using machine vision relies on expert-defined rules. The process typically involves:

- A quality control expert identifies relevant features in camera-captured images, such as edges, curves, and colors.

- They create a rule-based system to classify objects based on these features.

- The system then automatically decides if a product meets quality standards using these predefined rules.

While effective for many applications, this method has limitations.

D. Supply chain automation

#1. Fleet tracking and monitoring

AI-powered telematics solutions can help with real-time fleet tracking and monitoring in several ways:

- Instantaneous fleet monitoring: AI-enhanced telematics help monitor vehicle status, including location, speed, and fuel usage, in real-time. This helps make timely, informed decisions and rapidly address emerging issues.

- Driver behavior analytics: By leveraging telematics and AI, organizations can analyze driving habits and identify dangerous behaviors like speeding, sudden braking, and distracted driving.

- Asset tracking and monitoring: AI-powered asset tracking solutions use cameras, sensors, and GPS to provide real-time visibility into the location and status of vehicles, equipment, and cargo. This facilitates strategic routing and load-matching decisions.

- Fuel efficiency optimization: AI algorithms analyze vehicle sensor data, fuel card information, and historical consumption patterns to identify opportunities for improving fuel efficiency.

- Driver coaching and training: By monitoring driver behavior data, AI can identify areas for improvement and provide targeted coaching and training programs.

#2. Route optimization

One key benefit of AI in route optimization is real-time traffic analysis. AI systems can provide up-to-the-minute information on traffic conditions by processing vast amounts of data from GPS, traffic cameras, and mobile apps. This allows route optimization algorithms to dynamically adjust routes and avoid congestion, saving time and reducing fuel consumption.

Moreover, ML models can leverage historical patterns and external factors like weather to anticipate traffic bottlenecks and suggest alternative routes before they become problematic. AI also enables personalization, allowing route optimization to be tailored to individual preferences and needs, such as delivery time windows, customer instructions, and vehicle characteristics. This level of customization improves both efficiency and customer satisfaction.

How did Simform help a global logistic giant efficiently manage its vast network of deliveries?

Simform developed a sophisticated route optimization AI system for a global logistics provider operating in 30 countries. At its core, the solution uses machine learning to dynamically plan and adjust delivery routes. We combined advanced AI techniques like deep reinforcement learning and graph neural networks to represent and navigate complex road networks efficiently.

The system processes a variety of data inputs, including historical delivery patterns, real-time traffic updates, and weather forecasts. By analyzing this diverse data set, the AI can predict potential delays, identify optimal routes, and suggest proactive adjustments to delivery schedules.

We leveraged AWS services to build and deploy this solution. Amazon SageMaker provided the tools for developing and training our machine learning models, while AWS Lambda and Amazon EC2 enabled us to create a scalable, responsive system that can handle real-time data processing and decision-making.

#3. Order fulfillment

AI-powered analytics can analyze real-time data on inventory levels, sales trends, and customer demand to forecast future requirements accurately. This enables companies to optimize inventory positioning, minimize stockouts, and avoid costly excess stock, ensuring the right products are available at the right time and location.

AI algorithms can also automate and streamline critical warehouse operations, such as order picking, packing, and shipping. These systems can dynamically allocate resources, optimize workflows, and rapidly adjust to changing conditions, leading to improved throughput and reduced fulfillment times.

Zara has adopted AI and robotics to streamline its BOPIS (Buy Online, Pickup In-Store) service. AI robots fetch online orders from the warehouse to address long customer queues and waiting times. These robots can retrieve 2,400 packages, scan barcodes, and deliver items to designated pickup points. The automated system lets customers quickly retrieve their orders by entering a PIN and scanning a barcode. Zara has improved its online order fulfillment speed and efficiency by leveraging AI and robotics.

#4. Supply chain visibility

AI enhances supply chain visibility by enabling real-time tracking, monitoring, and data analysis across the network. Some critical applications include:

- Mapping supply chains: Large language models can synthesize data from product orders, customs declarations, and freight bookings to map a company’s multi-tier supply chain network.

- Demand sensing: AI systems can analyze data from point-of-sale systems, customer reviews, social media, and other sources to detect changes in demand patterns.

- Supply disruption detection: AI tools can monitor supply chain data to identify potential disruptions caused by port congestion, worker shortages, or natural disasters.

- Simulation and scenario analysis: AI can simulate different scenarios and evaluate the effectiveness of various strategies to mitigate supply chain disruptions, helping design optimal solutions.

Coca-Cola Andina, a beverage bottler in Latin America, wanted to improve its supply chain visibility. So the company built an internal app that provides real-time inventory, distribution, and delivery insights across its 10 plants and 100 distribution centers. The app pulls data from Amazon S3 and Amazon RDS. Coca-Cola Andina also harnesses the power of ML, using Amazon SageMaker to build models that predict delivery availability, reducing wasted attempts. It has led to a 0.2% reduction in out-of-stock and 0.3% fewer undelivered orders.

All in all, AI in supply chain has the potential to transform the industry holistically, from planning, sourcing, and procurement to quality control and supply chain automation. However, leveraging AI for supply chain is easier said than done. Like any other technology implementation, this too comes with its challenges.

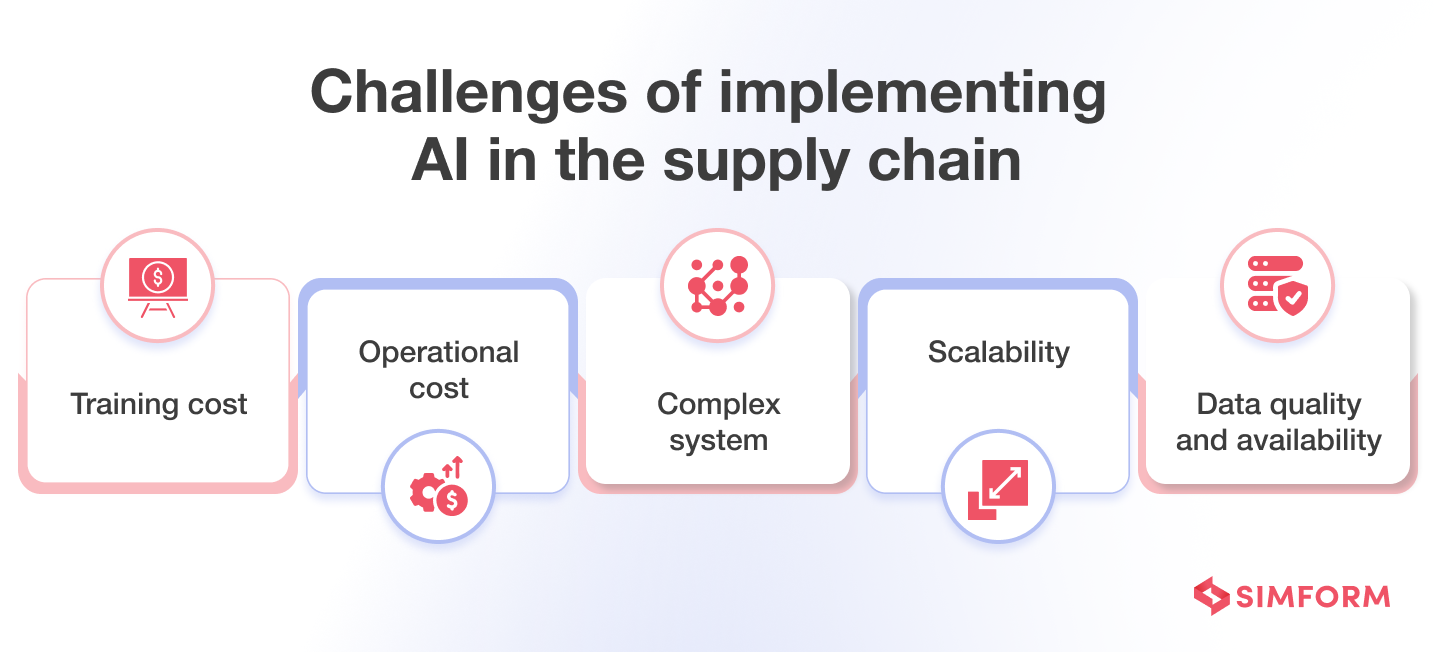

Challenges of implementing AI in the supply chain

Here are the major challenges that you may face while incorporating AI in their supply chain ecosystem:

Make your supply chain smart and future-ready with Simform

As we stand on the cusp of a new era in supply chain management, the question isn’t whether to adopt AI or not. It’s about how quickly you can take advantage of this transformative technology. However, integrating AI into your processes and systems efficiently requires a technology partner with deep knowledge and experience of AI in supply chains. That’s where Simform comes in.

As an AWS Supply Chain Competency partner, here’s how Simform can help:

- Develop custom generative AI solutions to automate tasks, generate accurate forecasts, and optimize supply chain operations.

- Build and deploy custom ML models to uncover data-driven insights and enable predictive maintenance and quality control.

- Create purpose-built LLM-powered solutions for supply chain use cases like intelligent chatbots, process automation, and knowledge management.

- Leverage AWS data services to build scalable data pipelines and apply advanced analytics to improve supply chain visibility.

- Migrate and modernize supply chain systems to the cloud for enhanced agility, cost-efficiency, and resilience.

Embrace the future of supply chain management with Simform. Contact us today to schedule a free consultation with our experts.